Need a Manufacturer?

Our Services.

As a LEAN manufacturer, we inspect and measure quality throughout the production process, starting with the raw materials and ending with the finished product.

Did you know?

We also participate in Kanban management to meet your Just-In-Time (JIT) requirements.

What we do

Our company manufactures fabricated sheet metal and wire products. In our over two million square feet of manufacturing facilities in two states, our employees manage various types of work cells to make sheet metal and wire products. We use enterprise resource planning software to automate key functions of our operation, especially as it relates to inventory management. As a LEAN manufacturer, we inspect and measure quality throughout the production process, starting with the raw materials and ending with the finished product. We also participate in Kanban management to meet your Just-In-Time (JIT) requirements. Also, BurnishOEM recycles 100 percent of the waste it accrues from our steel manufacturing operations. We take pride in recycling or repurposing leftovers associated with the manufacturing, cleaning, and packaging of our work. But we don’t just efficiently make parts, we also provide exceptional customer service. We staff call centers in both Texas and Alabama, and the friendly and responsive personnel will be available to answer your questions either on the phone or by email throughout the process.

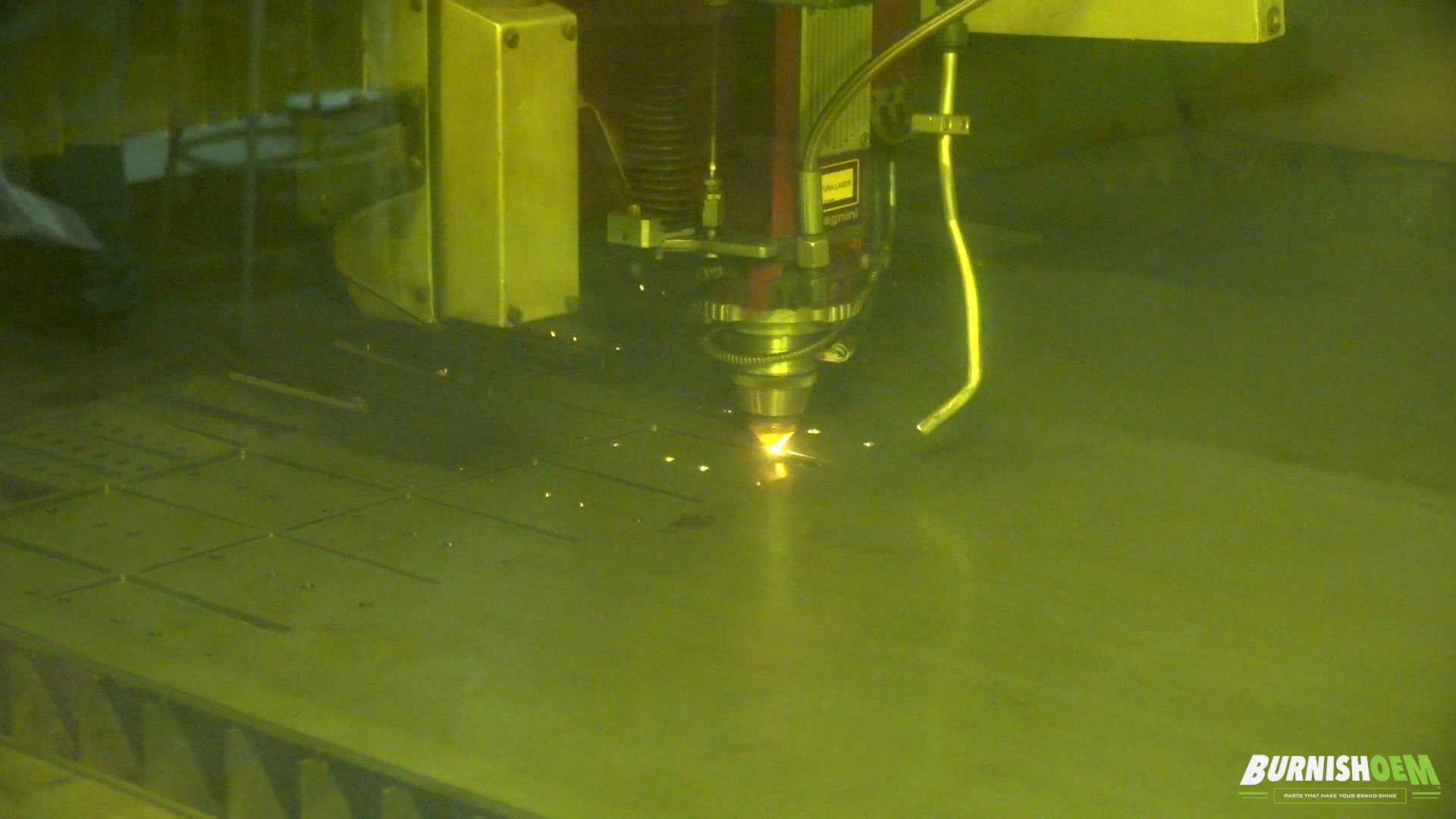

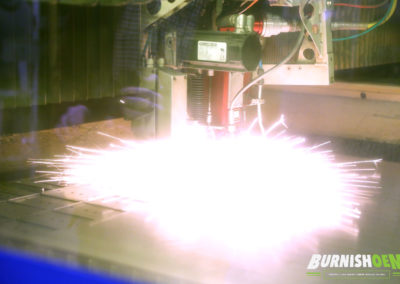

Cutting (CNC)

We cut both sheet metal and wire materials. BurnishOEM runs Salvagninnis laser systems for cutting sheet metal products. We also utilize automatic and cold saws to laser cut tubing. Laser cutting provides a cleaner edge than other forms of cutting. We also run sophisticated wire cutting and straightening equipment.

Video: Cutting (CNC) capabilities.

Photos: Cutting gallery

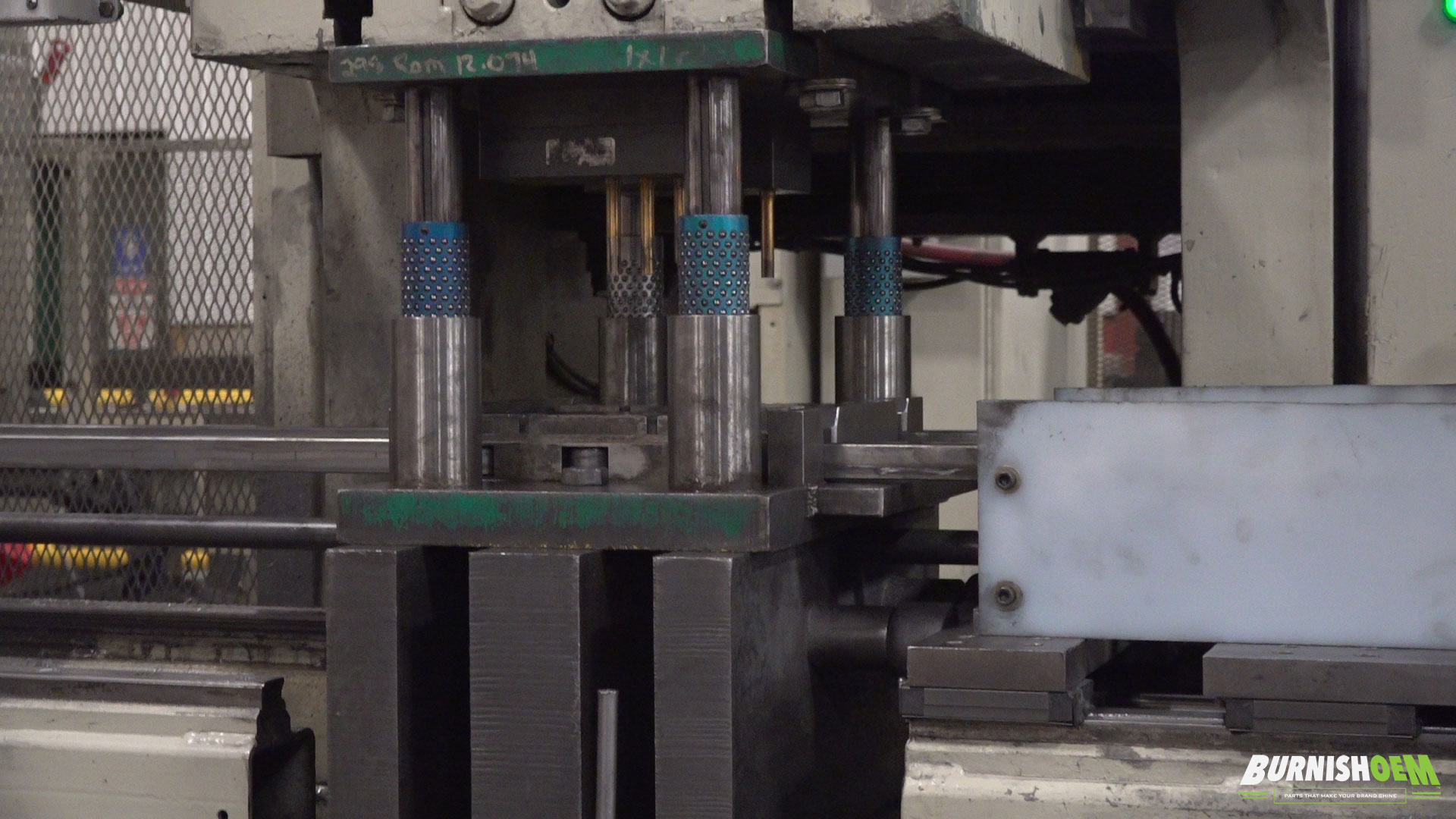

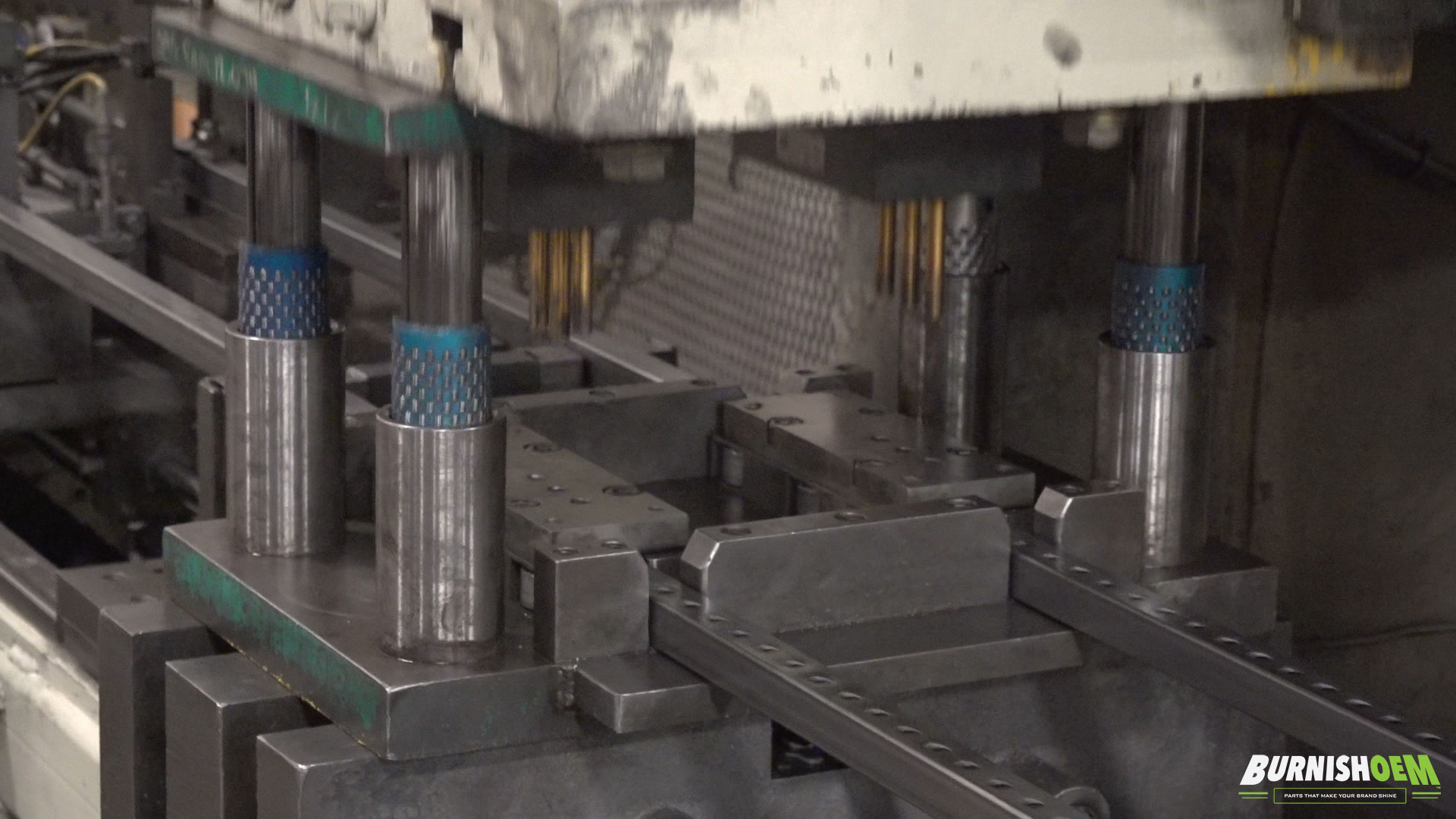

Die/Tooling Design

BurnishOEM designs, produces, and maintains its own dies, roll former tooling, weld tooling, and process/transfer lines. Dies are made in house for our customers’ projects. We control three separate tool and die departments in each factory, and each department houses its own wire EDM and CNC machinery.

Video: Die and tooling capabilities.

Photos: Die/tooling gallery

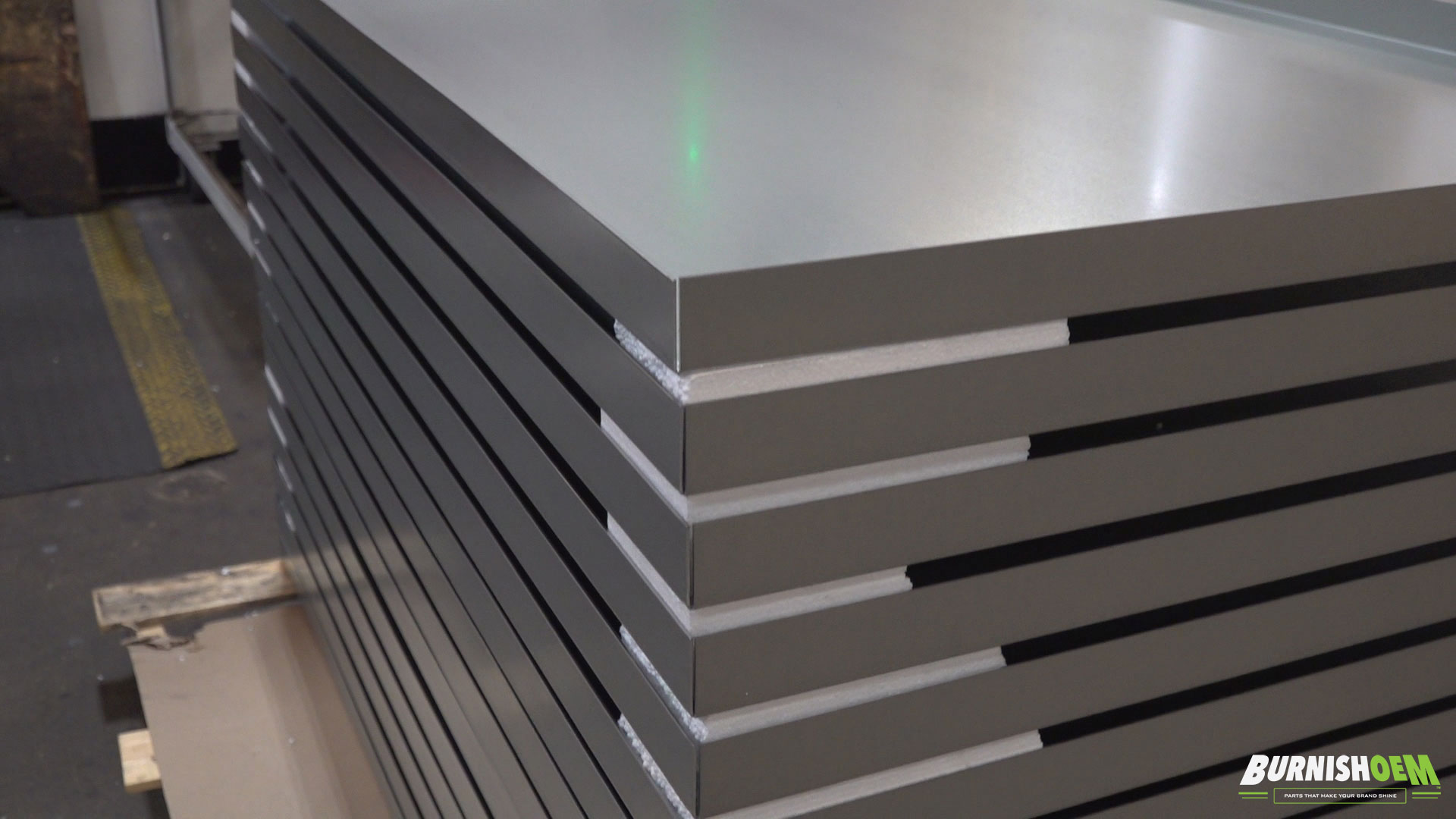

Finishing

We prepare metal parts for finishing by utilizing steam water parts washing, which includes phosphating. The parts move from washing to dry off ovens. After the parts are cleaned and dried, we paint them in one of several high speed, state-of-the art reclaim powder coating lines, each with multiple powder booths and associated equipment. We also operate numerous off-line manual powder booths for smaller projects. Once parts are painted, we cure them in our bake-off ovens.

Video: Finishing capabilities.

Photos: Finishing gallery

Kitting and Assembly

BurnishOEM operates assembly cells to facilitate assemblies and sub-assemblies. Our staff can deliver both metal and plastic component finishing. We can establish a program so we will deliver your product fully assembled (complete turn-key) to your desired locations, either packaged or unpackaged.

Video: Kitting and assembly

Photos: Kitting and assembly

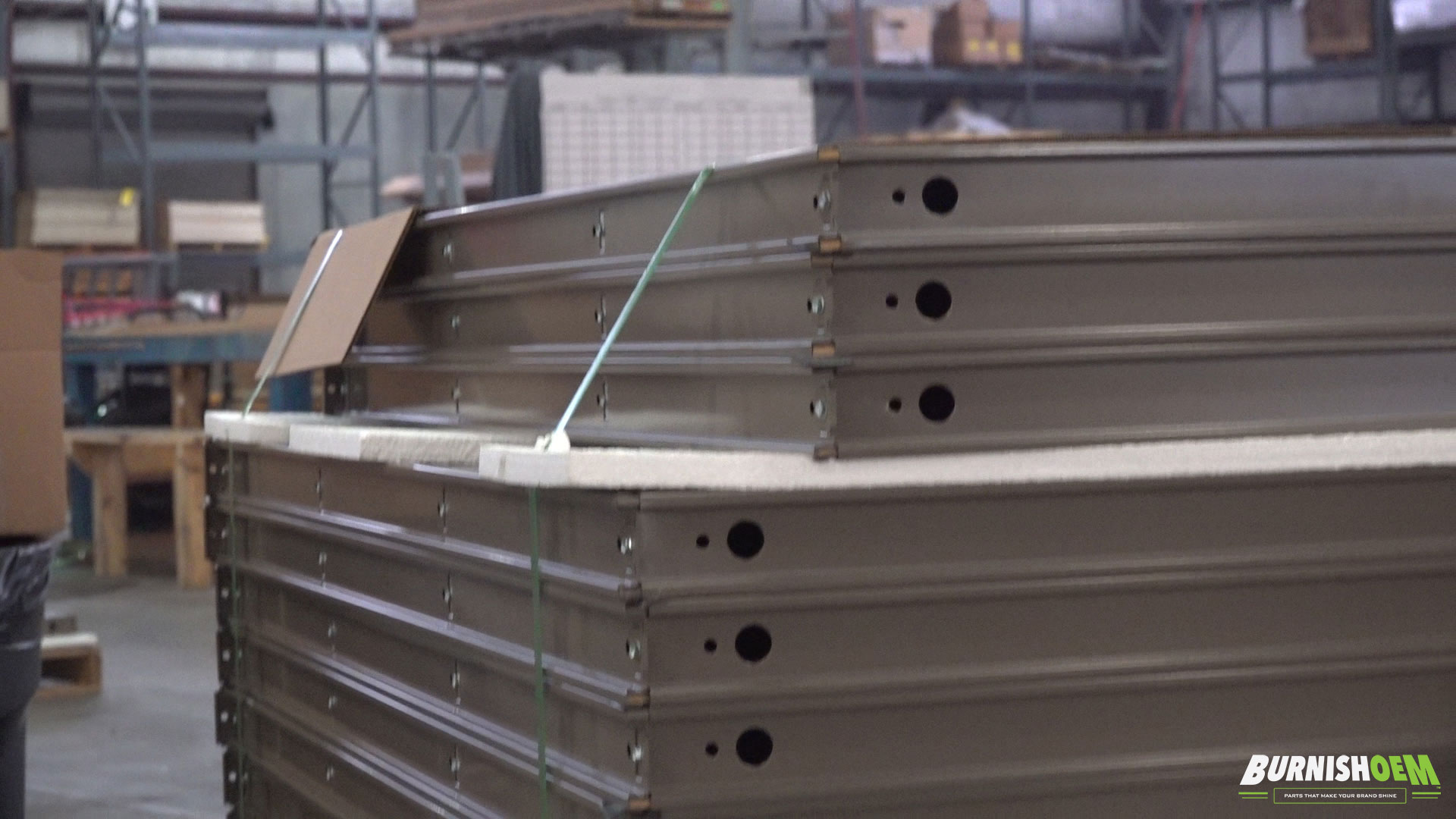

Metal Forming

Our employees are skilled at using our numerous presses to facilitate press brake forming. They produce parts quickly, identifying variations immediately to make corrections that alleviate defects. We also bend metal from sheet metal coil with CNC line equipment, utilizing computer-controlled feeders and straighteners. BurnishOEM can bend a wide range of metal grades, thicknesses, and sizes.

Video: Metal forming capabilities

Photos: Metal forming gallery

Packaging and Shipping

Our staff will either box or palletize product, and we have labeling. We also utilize automatic R-Pack shrink wrapping machines when needed.

BurnishOEM’s transportation departments provide timely deliveries by common carriers and LTL throughout the United States and by export worldwide. We are able to ship directly to distribution, to stock, and to customer sites. And we are able to ship to multiple points. Our company’s shipping capacity is broad. For example, we have 123 dock doors at our three manufacturing facilities to accommodate many truckload deliveries a day.

Video: Packaging and shipping capabilities

Photos: Packaging and shipping gallery

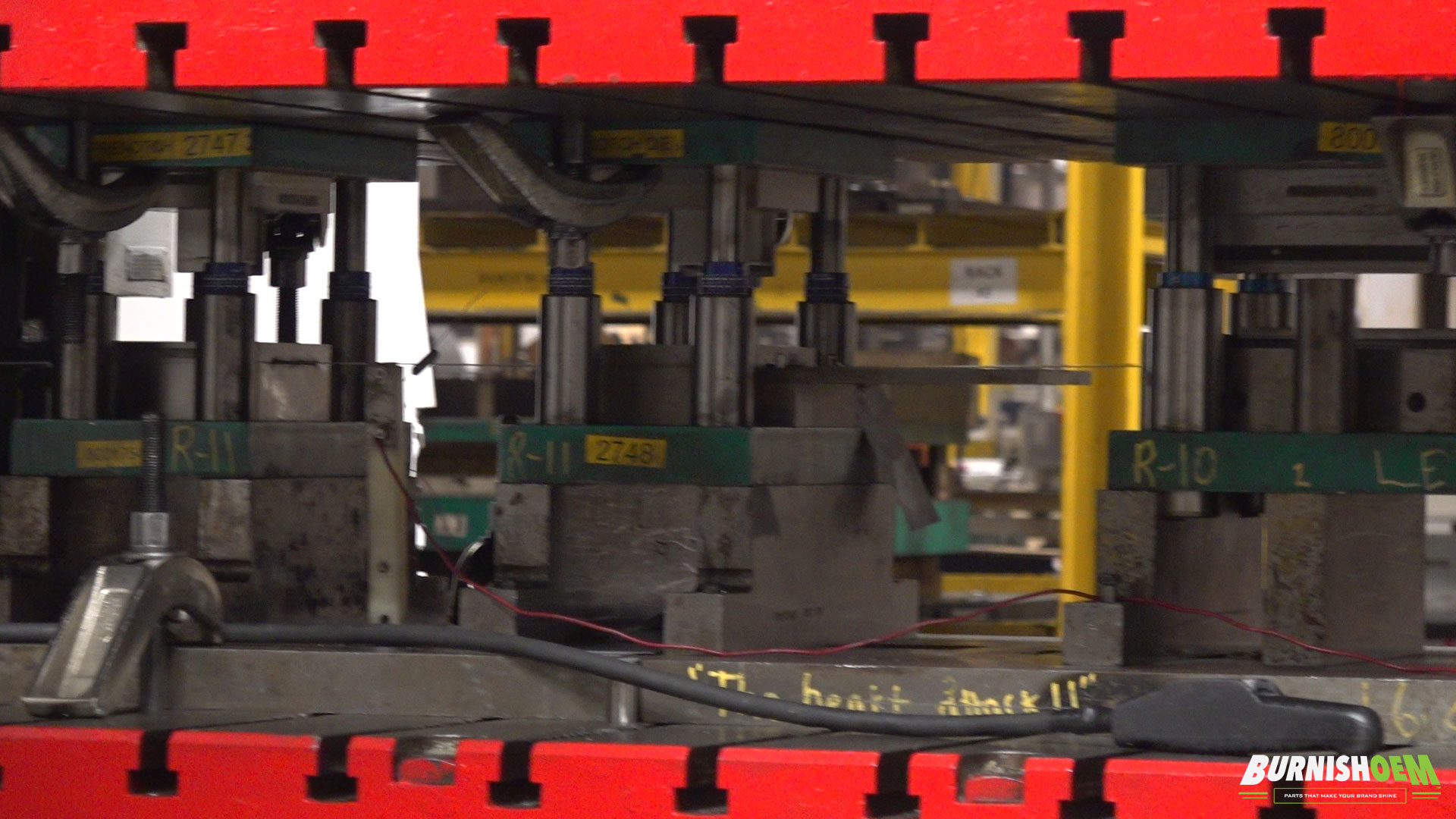

Stamping and Punching

We run both stamping and punching lines. We use turrets for stamping off steel coils. And we operate computer-controlled CNC equipment to shear, notch, and punch angles for flat pieces.

Video: Stamping and punching capabilities

Photos: Stamping and punching gallery

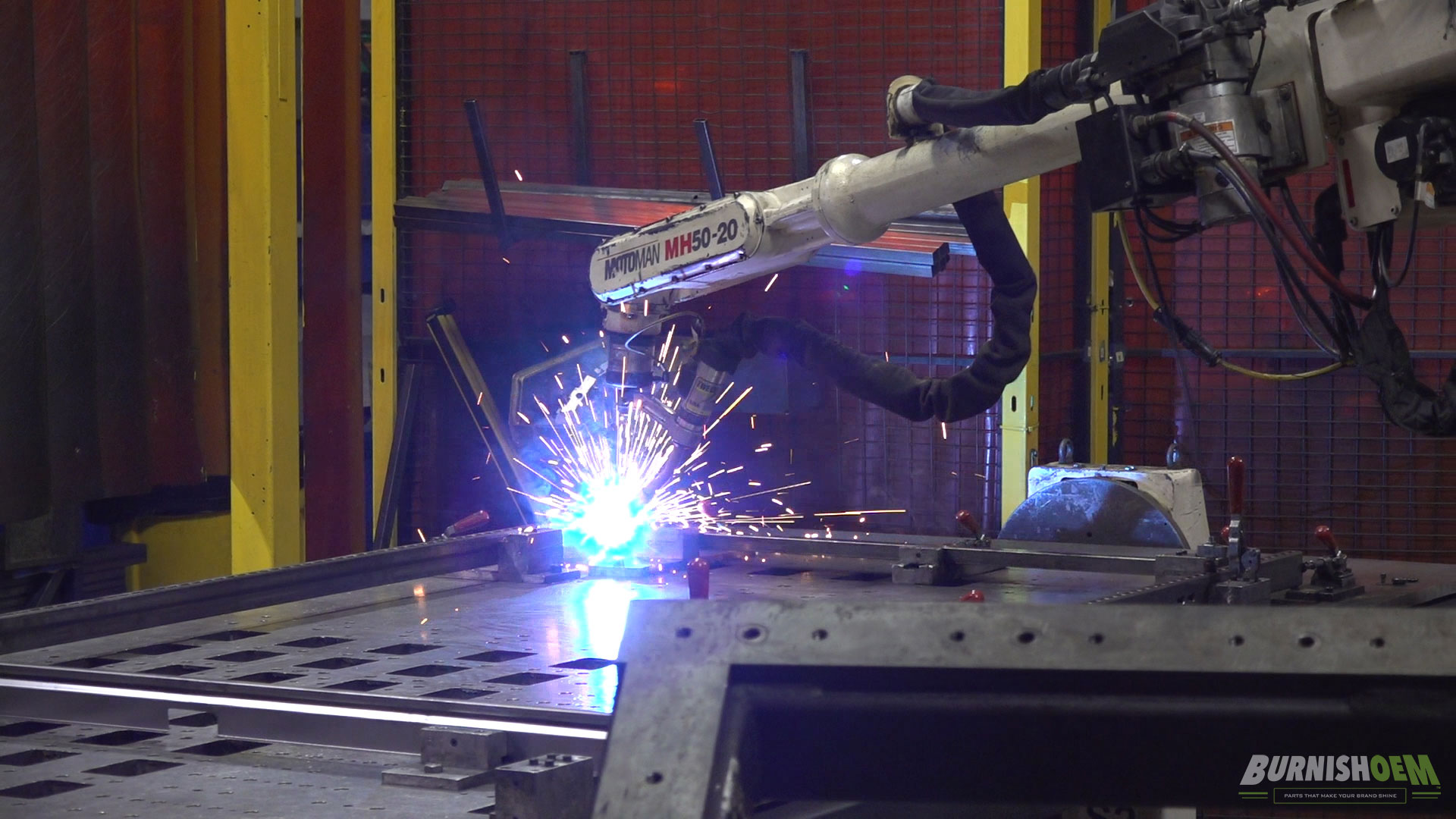

Welding

BurnishOEM manages high speed production lines with automatic spot and MIG welding. We weld both sheet metal and wire materials, utilizing both fully automated machinery and manual processes. Each plant facilitates complete welding departments capable of MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), resistance, and laser welding. We use not only certified welders but also sophisticated robotic welding equipment.

Video: Take a peek into our welding capabilities.

Photos: Welding gallery

Additional Services

Design and Prototyping

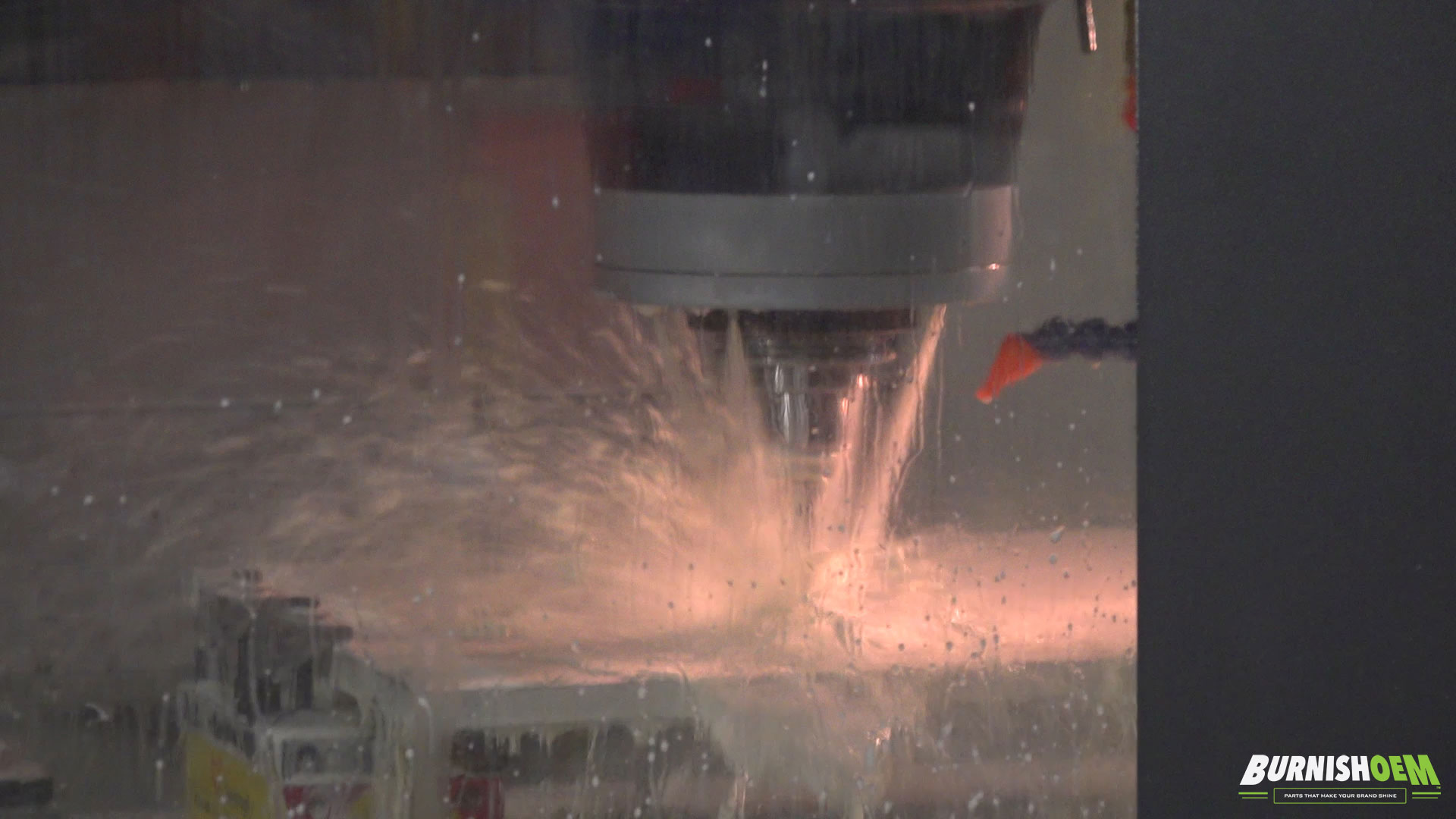

Machining

“

BurnishOEM delivers precision components that meet your exact demands and conditions for production, delivery, and management.

“